DECADES OF POWER SYSTEMS SAFETY SUCCESS

The Nation's Top Choice of Solar Fire Protection for Distribution Centers

Stay Protected, Achieve ESG & Earn Safety Credits

ThermalShield Systems Prevents Fires

Solar microgrid power inverters on distribution cause fires on a regular basis.

Our system is designed specifically to suppress these events.

Just like the sun that is coveted and feared, so are solar energy systems.

Thermal Shield Systems completely removes the fear of inverter fires.

What Causes Industrial Solar Inverters to Catch Fire?

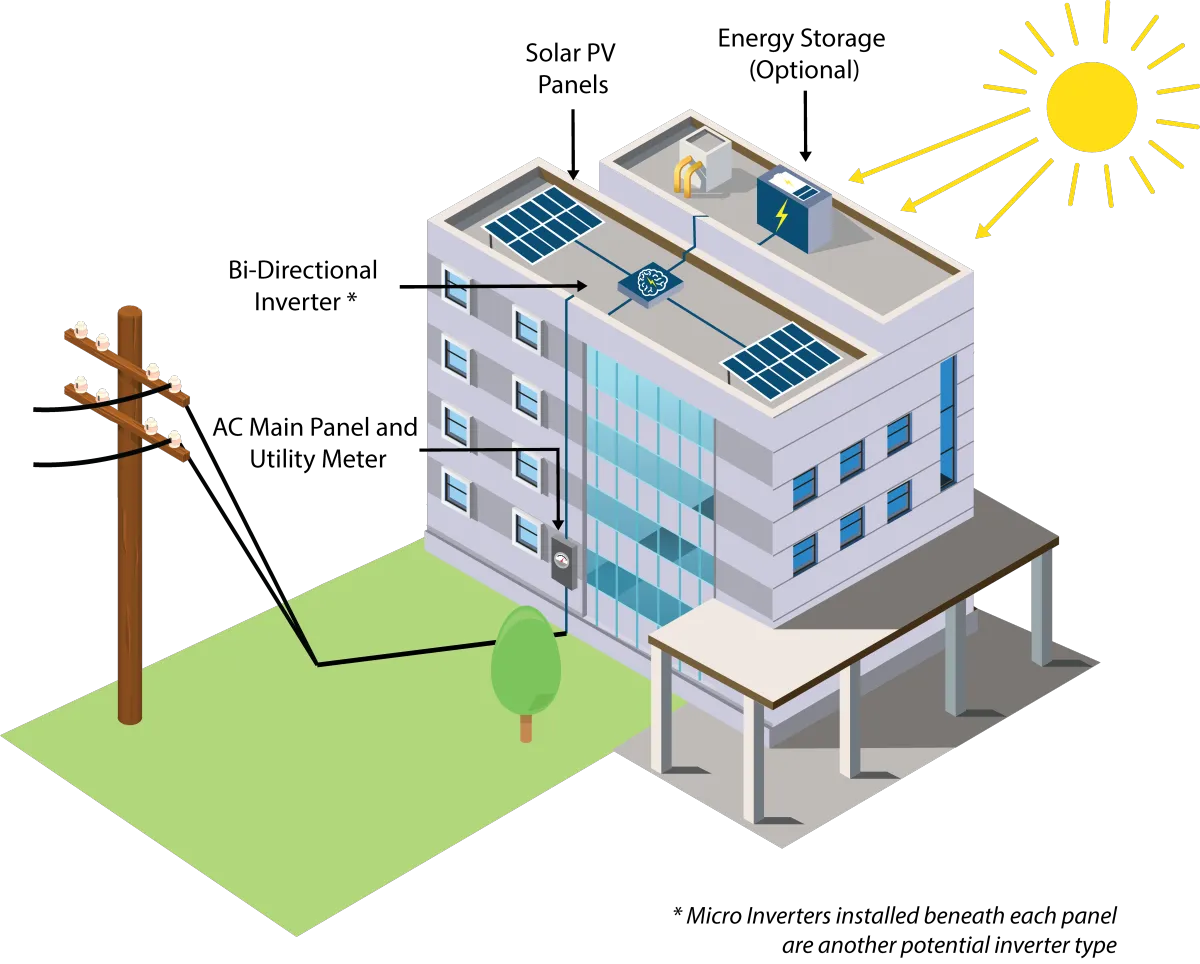

Some of the most socially responsible cold chain or U.S. distribution centers are installing solar microgrids on their roofs, and also creating solar farms from their trailers too.

A solar farm produces energy from the sun that can be used to offset traditional electricity consumption. It reduces distribution center's reliance on toxic fuels, which reduces its carbon footprint.

This is great! The fire and injury risks are not great.

DC connectors, are the second most common PV component causing fires.

A DC circuit connects the PV modules together and raises the voltage similar to connecting batteries in series. A parallel string of PV modules increases the current. The DC circuit is returned to the inverter, possibly through a DC isolator.

Metal contacts in DC connectors tend to stay connected due to frictional forces even after the supporting plastic body has burned out. Therefore, arc-exposed DC connectors should be suspected as a possible source of ignition.

Most solar energy systems use high voltage AC power. This can cause safety issues.

REVOLUTIONIZING FIRE SAFETY & ESG

INCENTIVES & BENEFITS PAYS FOR IT.

Achieves

Safety for all Parties

Eliminates cancerous emissions = zero carbon, zero toxins.

No More Inversion Fire

Danger or Fatalities

Safe! Low voltage runs on 46V DC & no ARC flash/electrocution risks.

Convert to Solar Without Fear

Embrace renewable energy & remove your reliance on the grid.

Ample Cost

Savings

Solar energy grids payback quickly, so don't fear leaning into solar.

$$$

Incentives

Safety incentives enhance your ROI & creates PR clout! Plus, you're keeping your people & DC safe.

Implement Your Plan Using Best Practices

We're all for going solar! It's very challenging to get it implemented flawlessly, and this is where it fails.

Do Solar Energy Grids Cause Fires?

Yes they do!

Especially solar power inverters, DC isolators.

No matter where a photovoltaic (PV) system is installed, there are significant fire risks.

Most of the fires are known to occur due to sub-par equipment, improperly sealed mechanisms, and sloppy installation of solar panels and connectors. This commonly leads to compromised electrical wiring and venerable components.

If a distribution center's solar farm is high voltage AC, there are well-known risks of electrocutions and fires.

Even if a PV system runs on high voltage or low voltage DC, arc flashes may occur because of poorly soldered cell connectors or soldering between cell connectors, and the busbars inside the module.

Sometimes, cross-mating connectors from two different manufactures can generate intense heat that affect components, or low-quality components such as junction boxes or cable connections.

Even artificial light sources from things like halogen lamps can cause a very expensive fire. Different components of a photovoltaic system. panel fires, It is common that the source of solar grid fires originate from the inverter combusting, or some aspect of the components of the solar grid.

Solar Energy Industries Association (SEIA):

It's all about standards & safety.

The world's first seamless & completely effective solar inverter fire protection system:

Easily integrated into new construction or retrofits

Lightweight

Impressively durable and resilient to elements

It truly is impenetrable and completely safe

Solid manufacturer's warranties behind it

Everyone wins!

Zero emissions and

cleaner air starts now.

We’re helping reefer truckers go the distance, low-voltage DC, CO2-free, maintenance-free!

Getting your goods there,

cleanly and safely.

The world’s only zero emissions beast that goes the distance

Pretty, Clean, & Quiet

Yet a Reliable Bad@$$ TRU

Winning 28'-53' Reefer Fleets

10+ years of tested and tortured zero emissions TRUs

Best-of-breed customers & fulfillment partners who deliver

CARB approved, & winning CORE vouchers, WAIRE & ESG credits

The only completely safe system using 46V DC - unregulated

Fast turnaround, AEM abides by stellar conversion processes

Zero maintenance, perfect safety record, zero range anxiety

Immediate & long-term savings, & AEM helps manage reporting

Founders who are unbeatable breakthrough engineers, & managers

Now also offering a SolarTechTRU modified for refrigerated trucks! See our comparisons page for specifications sheets on both models.

Unseating diesel-powered TRUs and other solar/electric powered TRUs with the proven and only surprisingly efficient, powerful, and proven-reliable, all-electric, solar-powered generator refrigeration system in the world.

It's so relieving to work with a company that truly appreciates the pain of downtime, and that knows how to rally our team so we're all working together with clarity to get our TRU conversions done, and to get our vouchers and credits.

Thank you Robert!

This has been one of our biggest initiatives in history, and thanks to the "seasoning" of AEM's engineering team, they've made this all seem so uncomplicated...and even a little fun...because they kept progress flowing, and we're seeing immediate payback of the SolarTechTRU, as promised.

It wasn't easy pulling the trigger and saying yes to converting our diesel TRUs to the SolarTechTRUs, but we sure are thrilled we've done this, and we'll continue doing this as we continue to grow. We're growing more profitably because of it too. I never expected to be able to 'go clean' and have it work out so well for us financially too!

Why should I feel completely safe, relieved, & thrilled to choose the AEM.green SolarTechTRU for my 28’-53’ reefer trailer fleet?

Warning!

Why you shouldn’t choose the AEM.green SolarTechTRU for your 28’-53’ reefer fleets…

No reason whatsoever!

AEM has innovated an onboarding, fulfillment, and ongoing support process that takes administrative, oversight, and workload burdens off your plate, while also eliminating emissions, electrical, and other safety regulations.

On top of all this, AEM.green has also engineered its SolarTechTRU to be so efficient it pays for itself in no time and can eliminate your reliance on the grid for the long haul.

Don’t Wait Any Longer.

Start Forging Your Zero Emissions Path Today!

Looking for a Zero Emissions TRU or a Safe Microgrid for your Cold Chain Distribution Center?

Contact www.AEM.green

Copyright Thermal Shield Systems ©2024 All rights reserved